The previous post was about canned foods. This one goes a step further and talks about can seams, where the body of the can and the lid of the can interlock. Can seams are a brilliant invention, and how they are formed is pretty interesting. Warning: this post is a bit like a technical manual. There are diagrams and information that are job specific. Don’t worry, it is really simple stuff, it’s just not everyday useful.

Introduction

Cans are hermetically sealed. If the seam isn’t formed correctly mircoorganisms can get into the can and contaminate the food. Metal cans have what is called a double seam, where the body of the can and the cover for the can come together.

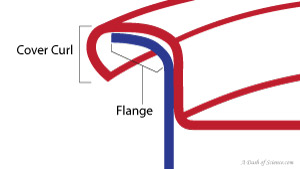

double seam: the closure at the end of a can, formed by interlocking and compressing the can cover curl and can body flange.

How Can Seams are Formed

A can is made of two or three parts: the top circular piece called a cover, the bottom circular piece, and the sheet of metal that forms a cylidar called the body. In a two piece can, such as a soda can, the bottom and sides of the can are made of one piece of metal. For three piece cans, the bottom is attached to the body of the can at the can factory. So canneries only have to attach the cover to the body of the can.

The can cover has its edge turned in. This is called the cover curl. It fits right over the flange of the can body. The flange is a flare in the metal of the body. After the seam is created the flange becomes the body hook and the cover curl becomes the cover hook. The can seam also has a sealing compound that is squirted onto the cover curl so it will fill in gaps between the two pieces of metal when the seam comes together. I didn’t include that in any of the diagrams because it becomes such a thin layer it would be hard to display.

To get the two pieces of metal to fold in on each other, a can is spun around while two specially shaped rollers, also spinning quickly, come alongside the can. The first operation seaming roll directs the cover inbetween the flange and the body. The second operation seaming roll flattens the seam. Watch these videos to see the process.

Parts of a Can Seam

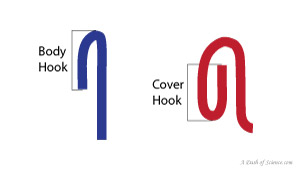

body hook: the metal from the body of the can that interlocks with the cover, from the tip of the flange to the bend.

cover hook: the metal where the cover bends around the body hook from the tip of the cover to its first bend.

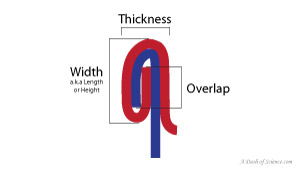

overlap: the distance where the cover hook and body hook overlap, where there are five layers of metal across the seam.

thickness: how wide the seam is at its thickest point.

width (aslo known as length or height): how long the seam is from top to bottom.

countersink: from the top of the seam to the cover of the can. It isn’t shown in the diagram above.

Why Can Seams are Inspected

Canned foods are the jackpot for microorganisms if they can get into the can after it has gone through thermal processing. There is plenty of food and no competition. So making sure the can isn’t compromise is very important. The most likely place for an opening in the can is at the can seam. Hence, the need to inspect can seams.

Inspecting Can Seams

At work I loved to check can seams. It requires an odd combination of manual labor, powertools, high tech equipment and technical knowledge. My lab was lucky enough to have special equipment and software from OneVision that made the job a lot easier. Checking by hand with a can seam micrometer takes much longer. Instead of going into detail on how cans seams are inspected, here is a video that shows off the OneVision SeamMate system. It is a little dry and skips my favorite parts of the process (cutting the can and stripping off the seam) but it is still informative if you need to learn the stuff. OneVision SeamMate Double Seam Can Inspection

Wrap Up

Now you know more than you ever wanted to know about can seams and a little bit about what a food quality technician might do for work. Next time you buy canned food, check out the can seam. If you find a dent, buy a different can.

Source:

- Canned Foods: Principles of Thermal Process Control, Acidification and Container Closure Evaluation, 7th Ed. Editor: Lisa M Weddig. GMA Science and Education Foundation. 2007

- “Single Head Can Seamer” by T-TEK Material Handling youtube video

Hey this post and video look great!

LikeLike

very nice ; love the extra dash of video and modern test apparatus; perfect blend of basics to cover the whole.

LikeLike

I have always wondered how food gets canned. Thank you for all the information about the process that they go through to get sealed. That is really cool that the two pieces of metal fold in on each other and it then gets flattened. No wonder it is so strong.

LikeLike

Thanks for helping me understand that seams are inspected since it will make sure that the food will not be compromised. I just got curious about these things because I heard my uncle that he needs to get cans seamed. It appears that it will be for the homemade food that he plans to sell online now that he has been approved of the loan he is applying for. This information will ensure that the food will be in good condition until it gets consumed.

LikeLike